TwinkleSteel, as a a professional manufacturer and exporter for metal building materials, including the steel coils, Aluminum Sheets, roofing tiles, 6 panel door skins, etc, and within 6 years development, we have earned some market share in the global. Sandwich panels, as a main applications with the metal sheets coils and next we make brief introduction.

*What is sandwich panel? The information below from Sandwich Panels.org

Composite Sandwich Panels are incredibly useful materials to form strong lightweight structures used in everyday life.

Sandwich panels using honeycomb, balsa, or foam are constantly helping to reduce weight and increase strength in a myriad of products today.

This site is dedicated to providing useful information on all aspects of lightweight composite sandwich panels from both an engineering point of view, and from a non-engineers perspective.

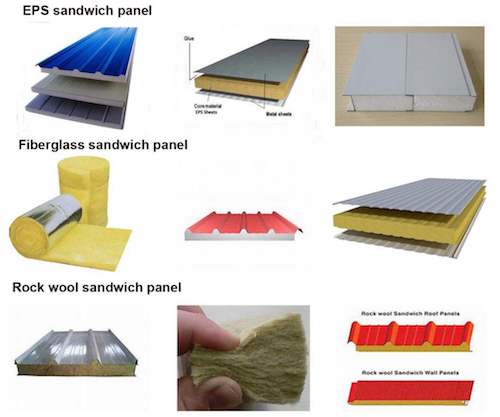

*4 kinds of sandwich panel in the world as the building materials

a.Insulated Glass Wool Sandwich Panel,

Painting of steel plates | PVDF, SMP, HDP, PE; The top painting should be above 25μm. |

Galvanized layer of steel plates | Exterior plate:55% Aluzinc above 100g/m³or Zinc coating above 150g/m³; Inner plate:55% Aluzinc above 70g/m³or Zinc coating above 100g/m³. |

Thickness of steel plates | 0.3mm-0.6mm. |

Thickness of core | 50mm/75mm/100mm/120mm/150mm. |

Density of core | 64kg/m³ |

Effective width | 950mm |

Panel Length | According to customers’ request |

b.Fireproof Rock Wool Sandwich Panel,

Painting of steel plates: | PVDF, SMP, HDP, PE; The top painting should be above 25μm. |

Galvanized layer of steel plates: | Exterior plate:55% Aluzinc above 100g/m³or Zinc coating above 150g/m³; Inner plate:55% Aluzinc above 70g/m³or Zinc coating above 100g/m³. |

Thickness of steel plates: | 0.3mm-0.6mm. |

Thickness ofcore: | 50mm/75mm/100mm/120mm/150mm. |

Density of core: | 90/100/120kg/m³ |

Effective width: | 950mm |

Panel Length: | According to customers’ request |

c.EPS Sandwich Panel,

Painting of steel plates: | PVDF, SMP, HDP, PE; The top painting should be above 25μm. |

Galvanized layer of steel plates: | Exterior plate:55% Aluzinc above 100g/m³or Zinc coating above 150g/m³; Inner plate:55% Aluzinc above 70g/m³or Zinc coating above 100g/m³. |

Thickness of steel plates: | 0.3mm-0.6mm. |

Thickness ofcore: | 50/75/100/150mm |

Density of core: | 10/12/14/16/18kg/m³ |

Effective width: | 950mm/980mm |

Panel Length: | According to customers’ request |

d.Insulated Polyurethane (PU) Sandwich Panel

Painting of steel plates: | PVDF, SMP, HDP, PE; The top painting should be above 25μm. |

Galvanized layer of steel plates: | Exterior plate:55% Aluzinc above 100g/m³or Zinc coating above 150g/m³; Inner plate:55% Aluzinc above 70g/m³or Zinc coating above 100g/m³. |

Thickness of steel plates: | 0.3mm-0.8mm. |

Thickness of core: | 50mm/75mm/100mm. |

Density of core: | 40-50kg/m³ |

Effective width: | 1000mm |

Panel Length: | According to customers’ request |

The common steel coils for sandwich panel, different countries have different demands, and the thickness, generally, 0.30, 0.35, 0,4, 0,45mm, the color is Ral9002, Ral8017, Ral3009. www dot twinklesteel dot com and aslo the zinc coating, and top and back painting thickness, and if the painting not good, there are many problems when you produce sandwich panels. So choosing a good supplier for ppgi steelcoils, it is very important, especially for a purchase manager or importer, they donot understand the present situation, and metal materials industry is a specail one and there are many rules which outside people do not know. Like zinc coating, somebody think, they quote 100g/m2, the real is 100g/m2 zinc coating? Maybe not. If you import more, you know the truth. Of course, if you just want cheaper price, maybe some supplier can do like this.