Product Introduction

Prepainted galvanized steel coils are used in a wide range of applications across various industries. Here are some common application fields for prepainted Galvanized Steel Coils:

Construction: Prepainted galvanized steel coils are used in the construction industry for roofing, siding, and wall cladding. The coils are used to create panels and sheets that are installed on buildings to protect them from the elements.

Appliances: Prepainted galvanized steel coils are used in the production of home appliances such as refrigerators, ovens, and washing machines. The coils are used for the outer shells of the appliances and provide a durable and attractive finish.

Automotive: Prepainted galvanized steel coils are used in the automotive industry for the production of parts such as car bodies, fenders, and hoods. The coils provide a strong and durable finish that protects the parts from corrosion and other damage.

Electrical: Prepainted galvanized steel coils are used in the electrical industry for the production of electrical cabinets, boxes, and enclosures. The coils provide a protective coating that prevents rust and other types of corrosion.

Packaging: Prepainted galvanized steel coils are used in the packaging industry for the production of food and beverage cans. The coils provide a protective coating that prevents corrosion and ensures that the contents of the cans remain fresh and safe to consume.

Overall, prepainted galvanized steel coils are a versatile and durable material that can be used in a wide range of applications in many different industries.

Today we mainly introduce the prepainted galvanized steel sheets and coils which are used for production of wheel barrow from TwinkleSteel Group.

PPGI (Pre-Painted Galvanized Iron) steel sheet is a type of steel sheet that has been coated with a layer of paint or a combination of paint and other protective coatings. It is commonly used in various applications where a durable and aesthetically pleasing finish is required.

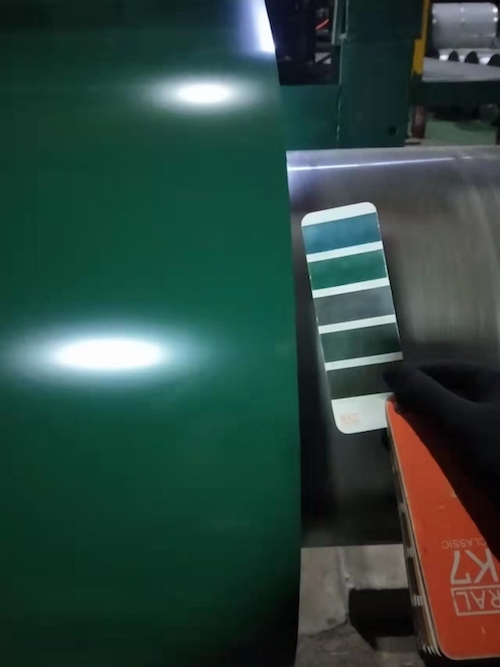

In the context of a wheelbarrow, PPGI steel sheet can be used for the body or tray of the wheelbarrow. The coating on the steel sheet provides corrosion resistance, protecting the underlying metal from rust and other forms of degradation. The pre-painted finish also enhances the appearance of the wheelbarrow, giving it a smooth and attractive surface.

PPGI steel sheets for wheelbarrows are typically manufactured with specific properties to meet the requirements of the application. These properties may include durability, impact resistance, and resistance to weathering. The thickness and composition of the steel sheet can vary depending on the manufacturer and the desired strength of the wheelbarrow.

Overall, using PPGI steel sheet for the wheelbarrow helps extend its lifespan by protecting it from environmental factors and providing an appealing finish.

The material of wheel barrow body, also know as tray or bucket, here we mainly talked about the steel sheet. The steel is used by galvainzed surface or powder-coated surface. Also this steel material can be suitable for stamping on moulds.

The steel sheet thickness can be 0.8-1.5mm (0.0315'' to 0.0591''). The thickness mainly depends on the final application, gardening, light or heavy construciton.

Here are some keywords related to color coated steel coils:

Color-coated steel coils

Galvanized steel coils

Steel sheet

Roofing materials

Corrugated steel sheets

Building materials

Metal roofing

Coil coating

Protective coating

Weather-resistant

Durable

High-quality finish

Anti-corrosion

Long-lasting

Attractive appearance

Industrial coatings

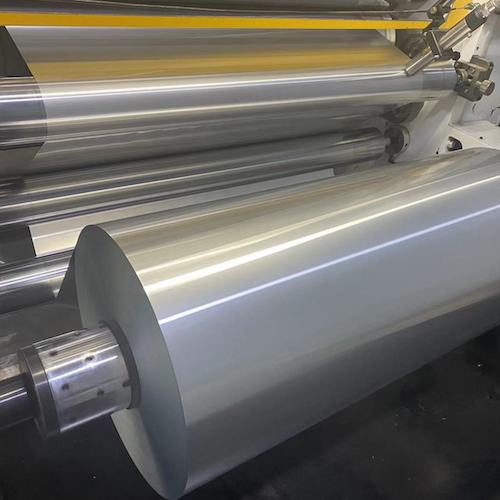

Coil coating process

Polyester coating

PVDF coating.

Certainly, here is some additional information about color-coated steel coils:

Composition: Color-coated steel coils are typically made of a steel substrate that is coated with a layer of paint or other protective material. The substrate can be galvanized steel, aluminized steel, or another type of steel.

Coating types: Color-coated steel coils can be coated with a range of different materials, including polyester, PVDF (polyvinylidene fluoride), and SMP (silicone-modified polyester). Each type of coating has its own unique properties, such as durability, weather resistance, and color retention.

Applications: Color-coated steel coils are used in a wide range of applications, including roofing, siding, wall panels, garage doors, and more. They are popular in industrial, commercial, and residential construction, as well as in the manufacturing of appliances and other products.

Benefits: Color-coated steel coils offer a range of benefits, including corrosion resistance, weather resistance, durability, and an attractive appearance. They are available in a wide range of colors and finishes, allowing for customization and versatility in design.

Manufacturing process: The manufacturing process for color-coated steel coils typically involves cleaning and pre-treating the steel substrate, applying a primer, applying the topcoat of paint or coating, and then curing the material to create a long-lasting finish.

Overall, color-coated steel coils are a versatile and durable material that offer many benefits for awide range of applications. They are available in a variety of colors and finishes, and can be customized to meet specific design and performance requirements.

Twinkle Steel, as a professional manufacturer and export for metal sheets and processing, with have rich experience in this field, including OEM roofing sheets, prepainted steel coils, Aluminum Sheets, tinplate, stainless steel, etc.

PPGI steel coils can be used for corrugating the sheet, tile, and sandwich panel, PU panel, steel door skin, ceiling channel, writing board, bookshelf, ari conditioner, billboard, etc. Below i will list the PPGI details in table.